Effective silage management can be a significant influencer to farm profitability. Silage making is a process UK farmers are well versed in, however, often face the same challenges year on year. Here we look at some key points to focus on during the fermentation and ensiling of forage.

Aims of Silage Making…

- Rapid pH drop to optimum level – between 3.8-4.2. Prior to ensiling, pH will be 5.6 and 6.6.

- Minimise loss of nutritional value. Increase the conversion of sugar and minimise protein degradation by achieving this rapid pH drop.

- Prevent spoilage by naturally occurring YEASTS, MOULDS & BACTERIA.

- Preserve the forage in a stable and palatable form.

- Control fermentation temperature and minimise aerobic activity at feed out or at the clamp face.

*Once ensiled, turning grass into silage is a microbial war:

- Heterofermentative bacteria, clostridia and nitrates all help to keep pH high and consume nutrients.

- Homofermentative bacteria produce lactic acid and drop pH rapidly.

The success of fermentation depends on how many of each type of bacteria (hetero and homo) there are in the clamp, and the conditions in which they are now in*

Critical Control Points

Fermentable carbohydrates (sugars)

- Target minimum 10% at harvest.

- Crop maturity, sunlight and time of cutting will affect this.

Anaerobic bacteria which will ferment and produce fermentation acids

- Avoid soil contamination which is a source for clostridia.

- Achieving optimum dry matter of 32 – 35% will help the correct bacteria thrive.

- Exclude oxygen as soon as possible

pH drops to 3.8 – 4.2

- Using a specific inoculant will help a rapid front end pH drop

Stable silage

- The drop in pH should now have stopped all microbial activity

- Ensure clamp is sealed to avoid oxygen entering the clamp. Use multiple sheets or a strong oxygen barrier

- Temperature should be within 5 – 10 degrees of the ambient temperature at time of harvest

Reduce feed out waste

- Keep a tight clamp face, oxygen can pass up to 1 metre into a clamp that has a loose face.

- Only take back the sheet as much as is necessary and keep a tight seal at the edge.

It is important to understand the need and mode of action of a silage inoculant to ensure the correct product is applied and expectations are managed

Frequently Ask Questions (and answers):

Will a silage inoculant make my poor grass into good quality silage?

No! Enzymes in some inoculants can help to release and increase energy. Fundamentally, an inoculant will help to keep the nutrients, including overall dry matter, and make them available for use at feed out.

If a crop looks good (high sugars) and the weather is good, should an inoculant be used?

Yes. Arguably, this is the most important time to use an inoculant as there are more nutrients available which could be used by either negative or beneficial bacteria. An inoculant can help to tip the balance.

Should an inoculant be specific to a particular forage?

No, although most inoculants are formulated to meet the needs of a particular forage type, making them crop specific. Essentially there are two key points an inoculant should meet:

- Front end pH drop

- Back End Stability

What’s more important? The number of bacteria or the type of bacteria?

Both are important, but the type of bacteria is probably the most important. Different bacteria types react differently in forages. For example, some bacteria’s work well in higher pH ranges, so make sure the bacteria type used meets the need of the crop.

So what type of bacteria is best to use?

Look at research for confirmation.

Strains of pentosaceus and plantarum bacteria have been researched and proven in the field to create a fast pH drop in varying conditions, essential for quick front end fermentation.

Bacteria types like brevis can aid back end stability during feed out, as this bacterium creates an acetic acid response which can help reduce yeast growth and heat.

What about enzymes, should they be included?

Yes. Enzymes help to unlock sugars bound tightly to fibres, increasing the ‘food source’ for the bacteria in order to ferment and produce acids. The use of enzymes can also increase forage digestibility.

*When Silaguard 50 enzyme pack was tested on silage against a controlled environment with no enzymes, it resulted in an increase of 0.45 MJ/kg DM (ME).

Does using a silage inoculant really pay?

Research on silage inoculants is conducted all over the world, where it is widely regarded that using a proven silage inoculant offers a significant cost benefit to the farmer.

Assuming the above increase in ME alone: at 12kg DM intake of silage/day, the energy gain of 5.4 MJ is equivalent to 1 litre/head/day.

At a cost of inoculant application of £1.35/t fresh weight, the milk yield response stated above from 1-tonne fresh weight of silage assuming a milk price of 26ppl is £37.44 worth of milk.

NWF Silage Additives

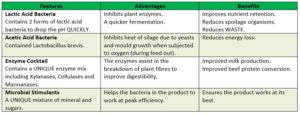

NWF Sila-Guard 50

NWF Sila-Guard 50 contains quick-acting bacteria and enzymes that converts valuable crop carbohydrates into energy for milk production. The additive has been formulated to produce high-quality silage with a balanced acid profile for your livestock. Designed for UK weather and UK grasses. It has an exclusive lactic acid mix.

The NWF silage inoculant range is supplied in 150g pots, each treating 50 tonnes of silage. For high dry matter, the concentration can be increased to suit requirements.

NWF Sila-Guard 45

NWF Sila-Guard 45 offers exceptional quality and value in conversation technology. The additive is a premixture of technological feed additives including Pedicoccus pentosaceus and Lactobacillus plantarum, unlocks energy and reduces nutrient loss.

Sila- Guard 45 does not contain Enzymes, for farmers who feel their crop does not require the extra impact on digestibility.

The unique blend of lactic acid-producing bacteria in Sila-Guard 45 optimises the speed with which pH drops after ensiling. The value in these results from minimising nutrient loss and creating a more stable silage after ensiling. The bacteria in Sila-Guard 45 stimulate the inoculant when added to the silage, ensuring maximum activity.

Each 150g jar is sufficient to treat 50 tonnes of fresh forage. Add contents of each jar to 50L of fresh, clean water and mix thoroughly. Apply to forage at 1 litre per tonne of fresh forage. Sila-Guard 45 Can also be applied through all low volume application systems.

NWF Sila- Guard Maize | NWF Sila-Guard Whole Crop

NWF Sila-Guard Maize is a premixture of technological additives containing:

- Fermentation Starter- Pediococcus pentosaceus. Optimum pH range 7.0 to 5.0. Dominates spoilage organisms.

- Fermentation Finisher- Lactobacillus plantarum. Optimum pH range 5.5 to 4.0. Ensures full fermentation and stable silage.

NWF Sila-Maize contains enzymes, and NWF Sila- Whole Crop also has the addition of LACTOBACILLUS BREVIS, an aerobic stability enhancer, to control production of acetic acid for palatability with stability.

Gaining the maximum effect of silage inoculants can only be achieved when used alongside quality management and ensiling conditions. Consult NWF’s trained advisors to help achieve quality and profitable silage.

For more information on NWF Silage Additives, speak to your local NWF Sales Specialist, or click HERE to read more.